Learn to make a counter height bench to fit your kitchen island with these step-by-step instructions.

Hello friends! Thanks so much for all the love on our recent kitchen remodel post. It feels so good to have a space that truly reflects my taste.

I’ve been getting a lot of questions about the bench at our kitchen island. I was so tired of barstools being scattered all around the house and never being tucked in straight even when they were at the island. I also searched the entire internet looking for new barstools, but didn’t really love anything enough to pull the trigger. So I decided to do what I always do and DIY it!

This is an intermediate woodworking project. If you’ve build furniture before and know how to use the tools, you can handle it. Here’s what you’ll need to get started:

Step 1: Gather Materials + Purchase Wood

Tools Needed

- Miter Saw

- Table Saw

- Router, ½ inch Roundover Bit and ½ inch Cove Bit

- 3/8” Countersink Bit

- Kreg Jig

- Pneumatic Finish Nailer

- Drill

- Clamps

- Oscillating Tool

- Orbital Sander

- Tri-Square or Combination Square

Materials Needed

- Wood Glue

- Kreg Screws, 1.5 inch

- Wood Screws, 1.5 inch

- Finish Nails, 1.5 inch

- Finish Nails, 1 inch

- 3/8 Wood Dowel

- Sandpaper (60, 120, 220, 400 grit)

- Wood Filler

- Latex Paint

- Paint Brush

- Wood Conditioner

- Wood Stain (Briarsmoke and Dark Walnut)

- Wipe On Polyurethane

Wood To Purchase

- (3) Pine 1x4x8′

- (2) Pine 2x2x8′

- (1) Pine 1x2x8′

- (1) Poplar 1x2x8′

- (1) Poplar 1x2x3′

- (2) Poplar 1x4x8′

We used pine for the base of the bench since it’s less expensive and we painted it. Since we wanted to stain the seat, we went with poplar because we liked the look.

Step 2: Cutting

We found it most efficient to cut the individual pieces as follows:

Cut List

Pine:

- 1x4x8′ – four 13” pieces and four 6-1/2” pieces

- 1x4x8′ – four 20” pieces and four 3-1/2” pieces

- 1x4x8′ – two 46-1/2” pieces

- 1x2x8′ – two 13-1/2” pieces (these will need to be ripped down to a 1×1 nominal size (3/4×3/4 actual))

- 2x2x8′ – one 33” piece, four 10-1/2” pieces, and two 9-3/4” pieces

- 2x2x8′ – four 11-1/2” pieces

Poplar:

Poplar is sold by the linear foot, so I recommend the following sizes:

- 1x2x8′ – two 46-1/2” pieces

- 1x2x3′ – two 15” pieces

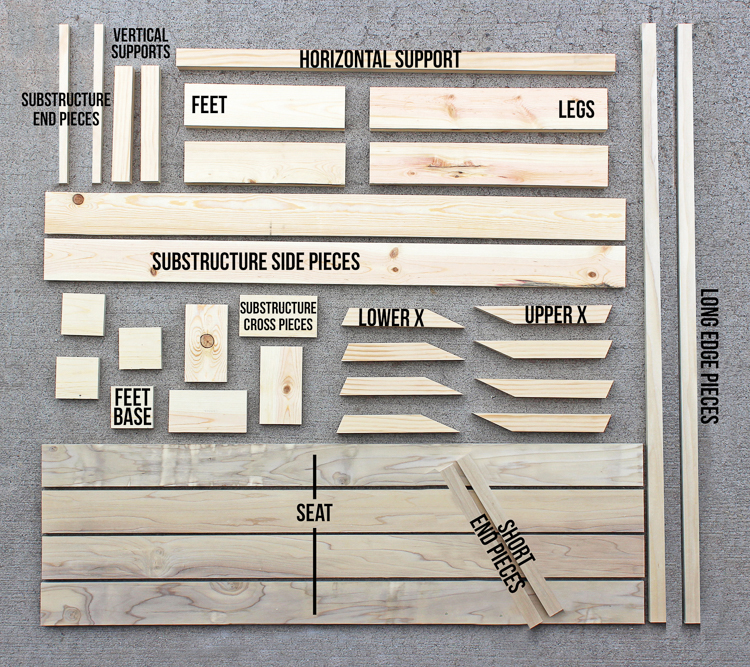

Parts List

You will notice that 2x4s are listed below in the Parts List but not above in the Cut List. The reason for this is that we created our own 2x4s. We did this because the corners on 2x4s are not square but are usually rounded to some degree. Others have overcome this by trimming the edges off, but for us this would have altered many of the other measurements. So rather than adjust all the measurements we glued and clamped two 1x4s together to achieve the desired dimensions while maintaining crisp corners. The result is that below in the Parts List you will see 2x4s listed instead of the more numerous 1x4s from above.

Pine:

- (2) 2×4 – 13” feet

- (2) 2×4 – 20” legs

- (4) 1×4 – 3-1/2” feet base

- (4) 1×4 – 6-1/2” substructure cross piece

- (2) 1×4 – 46-1/2” substructure side piece

- (1) 2×2 – 33” horizontal support

- (4) 2×2 – 10-1/2” lower X

- (4) 2×2 – 11-1/2” upper X

- (2) 2×2 – 9-3/4” vertical support

- (2) 1×1 – 13-1/2” substructure end piece

Poplar:

- (2) 1×2 – 15” short end pieces

- (2) 1×2 – 46-1/2” long edge pieces

- (4) 1×4 – 46-1/2” seat

With the exception of the upper and lower X pieces all of the pieces should be cut square. For the upper and lower X pieces, the cuts will be the same but the lengths will be different. The cut on one end of the X will be 24 degrees and you will have to adjust your miter saw to that angle. The cut on the other end is the 90 degree reciprocal making it a 66 degree cut. Typically a miter saw can be positioned up to a 45 degree angle but not as far as the 66 degrees needed. The solution is simple however. Rotate your X piece 90 degrees. This puts the short side against the miter fence. Having this short edge against the fence creates instability in the work piece, but again there is a solution. Clamp a piece of scrap wood with square edges to the miter table and use it as a temporary fence to hold the X piece for the 66 degree cut. As is true any time you’re working with power tools be very mindful of the position of the saw blade and your fingers.

Step 3: Feet

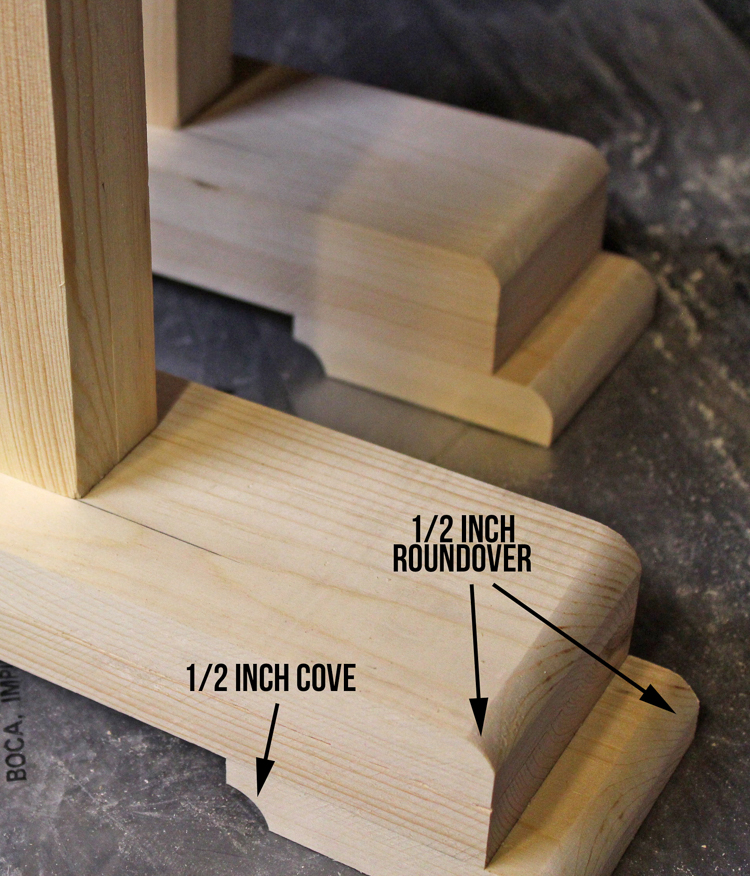

Starting from the bottom up, we began with the feet. The base of the feet is routed using a 1/2” round-over bit and a 1/2” cove bit as shown.

Next the 2×4 piece of each foot will need the top corners routed using the 1/2” round-over bit.

The final step for the feet is to glue and nail the base of the feet to the 2×4. This is easiest if the pieces are glued and clamped in place before nailing. A pneumatic finish nailer with 1 ½” nails makes the job a snap. The foot base piece extends ¾ inch beyond the end of the 2×4 foot.

Step 4: Legs

The legs all need to be screwed together rather than nailed. The first step is to center the legs on the feet. Then beginning on the bottom side of the feet and using a countersink bit, drill two holes into the foot to attach the 2×4 leg and one hole for each X part of the lower leg.

Using the layout lines on the top of the feet, glue and screw the 2×4 leg to the foot.

Next two counter sink holes will need to be drilled into both the upper and lower X part the leg as shown. Prior to drilling the holes, use a square to draw reference lines on to the leg. These lines will allow you to drill the countersink holes at the proper angle.

Once the 2×4 leg is attached, glue and screw the lower X part of the legs in place. Lastly, to ensure that the upper X part of the legs is properly situated, using a flat surface turn the leg upside down with the foot in the air. If your measurement and cuts are correct the upper part of the X should sit flush on the flat surface and should just meet the lower part of the X where they attach to the 2×4 leg. Apply glue and screw the upper X into place.

Step 5: Substructure

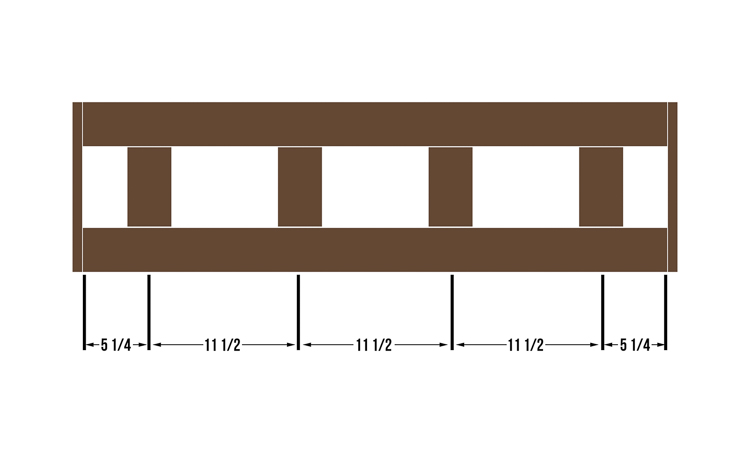

Lay out the substructure pieces as shown below.

Begin drilling holes using your Kreg jig. Each cross piece will need two holes on each end. After the holes are drilled, use clamps, glue, and Kreg screws along with the accompanying Kreg bit to assemble the substructure. Lastly glue and nail the 1×1 end pieces into place.

Step 6: Center Supports Installation and Assembly

The 2×2 horizontal support will be centered front to back in the middle of the 2×4 leg and aligned vertically in the middle of the X. A single countersink hole needs to be drilled beginning on the outside of the leg.

The two countersink holes need to be drilled 10 ¾ inches from each end in the horizontal cross piece. These will be the attachment point for the two vertical support pieces.

Glue, clamp and screw the two vertical support pieces to the horizontal cross piece.

Glue and screw the horizontal cross piece to each leg.

Using the countersink bit, drill holes in the cross pieces of the substructure that correspond with the top of the 2×4 leg, the upper X part of the leg, and the vertical support pieces. Glue and screw the substructure to the legs and vertical support pieces.

Step 7: Filling Countersink Holes

Often countersink holes are filled using pre-made buttons or plugs. Because the holes on the X part of the legs are an unusual angle, using pre-made plugs will not work. Instead, we glued a 3/8” dowel cut into short pieces into the holes.

Once the glue is dry, cut them flush using an oscillating tool or saw.

Sand the dowels smooth.

Sand the entire bench base before continuing.

Step 8: Seat

Begin by edge gluing and clamping the 1×4 seat pieces together. Let dry overnight. The seat will be 14” wide and need to be ripped down to 13 ½ ” wide. Using a table saw remove 1/4” from each long edge. Glue and nail the two long 1×2 edge pieces to the seat. Finally, glue and nail the two short end pieces to the seat.

Slip the completed seat over the substructure and using 1 inch nails, secure into place.

Using wood putty fill in exposed nail holes in the seat.

Finish sand by using a large 60 grit sandpaper followed by medium 120 grit and 220 grit sandpapers. Finish the preparation for stain on the bench seat by using a 400 grit sandpaper.

Paint the bench base using satin latex paint.

Stain the bench seat and coat with polyurethane.

The top of the bench seat is the same height that a normal counter height stool would be. The best part about having a bench instead of stools is that three or even four kids can sit at the island together, depending on their age and size.

If you’ve got questions on this project, leave a comment and I’ll try to help you through. Thanks for stopping by!

Comments & Reviews

I love that.Good job! and Way to go on Home Depots Site!!

Hey your bench looks great! I’m building it right now and it seems some of the measurements on the blog don’t add up. The substructure side pieces are listed at 46 1/2 in. long, Are you sure they shouldn’t be shorter? I ask because the spacing of the cross pieces doesn’t add up correctly to 46 1/2 (5 1/4 + 11 1/2 + 11 1/2 + 11 1/2 + 5 1/4). Instead of equaling 46 1/2 inches it seems the substructure side pieces should be 45 in. With the two added end pieces (3/4 in. a apiece) then it should equal 46 1/2. Am I missing something?

Good catch! You are absolutely right.

This is such a neat bench. Exactly, what I have been looking for and haven’t been able to find. And, like you, I decided to DIY. I do this a lot! 🙂 You have inspired me!

Do you have a picture of under the bench seat? I love visuals.

Thank you so much,

Ashley.